Hey y’all. Sorry I missed you last week. Was down on Whidbey for the first knitting retreat since 2019!

Was awesome to be back at the Aerie- a great place to gather and hang loose.

I got a little bit of knitting and spinning done, but mostly it was just about reconnecting with my knitting peeps. 🙂

On the way down I stopped of briefly in Coupeville to visit Sea Bre’s Yarn which is newly renovated and really lovely. Picked up a smidge of Schoppel Edition 3 (like Zauberball, but a little thicker) in the Tante Emma colorway. I just can’t resist that stuff. Also popped into A Touch of Dutch for black licorice.

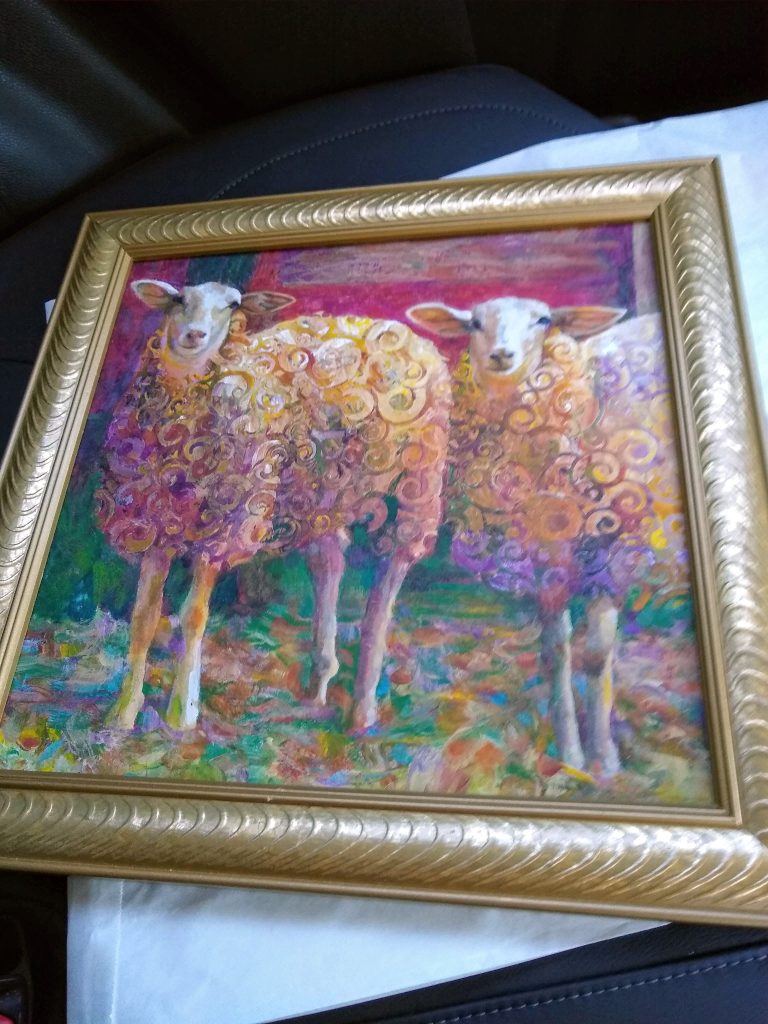

Saturday we ventured out to Langley, and on the way found we were just in time for the Bayview Farmer’s Market. Lots of beautiful and interesting wares, but you probably won’t be shocked to see what caught my eye

Yep. Sheep Art.

You had me at “Hello”. 🙂

So those little cuties came home with me and now adorn my home office wall.

We also checked out a very new Yarn shop in Clinton- Skein & Tipple. Originally thought we might stay after yarn browsing to enjoy a cocktail at the bar, but it turns out that the shop is super tiny and only operates as one thing at a time, with a half-hour intermission to reconfigure itself in-between. I picked up a little tiny pair of circular needles (size 2, 9″ long) to add to my toolbox, but stayed strong and resisted the hand-dyed yarn selections.

It was only after I’d returned from my weekend adventure that I realized that my yarn and needle selections were perfectly matched, and cast on for a pair of mittens.

I have since finished that first mitten, and based on the weight of it (26 grams) and the remaining yarn (26 grams), I might just use every last inch of this yarn!

It’s been cool and rainy since my return, so I’ve been knitting in the hoophouse, where the peas are enjoying being sheltered- and finally putting on some pods

And tomatoes and peppers are making incremental process, waiting for summer (or even real spring? ) to arrive

So that’s the scoop. Mittens in May. And hopefully more sunshine on the way(?)

Have a good week everyone-